What to Consider When Ordering Custom Cutting Edges

When it comes to specialized machinery and equipment, the efficiency and durability of cutting edges are crucial. Whether you're in construction, agriculture, or another heavy-duty industry, the right cutting edge can significantly impact productivity and operational costs. In this blog post, we'll delve into what you need to consider when ordering custom cutting edges to ensure you get what's best for your specific needs.

Choosing the Right Material for Durability

The first factor to consider is the material of the cutting edge. Cutting edges can be made from various materials, including carbon steel, boron steel, and carbide. Each material offers different benefits; for instance, boron steel provides excellent wear resistance, making it ideal for high-impact environments. Selecting a cutting edge with the right material ensures a balance between durability and cost-effectiveness. The right choice can make a cutting edge not only longer-lasting but also capable of handling the specific demands of your operation.

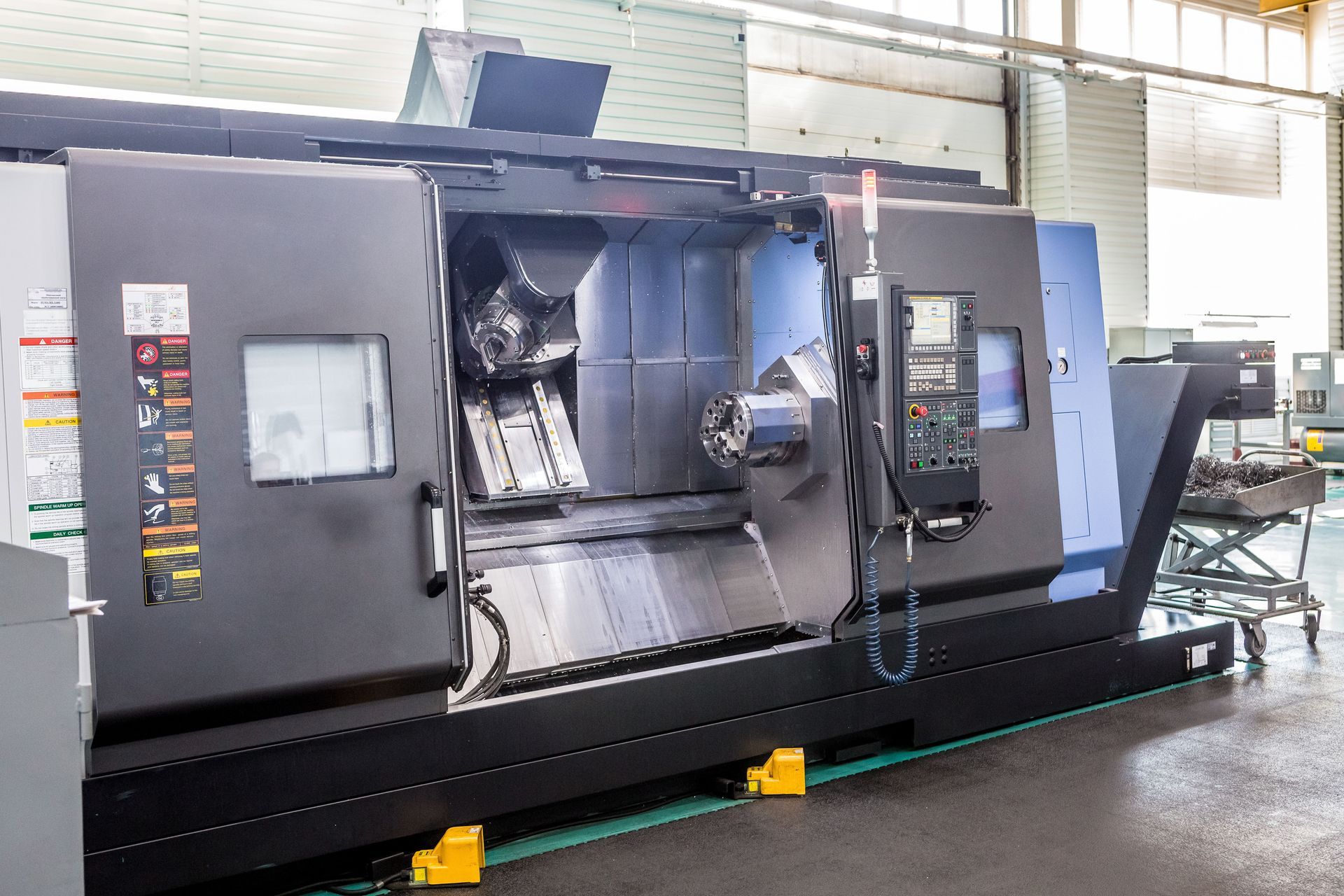

Assessing Manufacturer Expertise and Capabilities

Another important consideration is the manufacturing capabilities of your supplier. According to IBISWorld, in the United States, there are 3,431 fabricated structural metal manufacturing businesses, but not all specialize in custom cutting edges. You need to ensure that the manufacturer you choose has the right expertise and equipment to deliver high-quality, precise products. Working with a high-quality manufacturer ensures that your custom cutting edge meets the highest standards, resulting in better performance and longevity. Reviewing their past projects and customer feedback can provide insight into their reliability and quality.

Designing for Performance and Efficiency

The design of the cutting edge is also crucial. Custom cutting edges should be designed to match the specific requirements of your machinery and the type of work it will be doing. Collaborating closely with the manufacturer during the design process can help in creating a

cutting edge that maximizes efficiency and minimizes downtime. Consider aspects like the edge's thickness, length, and curvature, as these can all influence the cutting performance and lifespan. A design tailored to your needs enhances operational efficiency and reduces maintenance over time.

By paying close attention to these aspects, you can ensure that you receive a cutting edge that not only meets but exceeds your expectations. Contact Ray-Mac, Inc today to learn more or to get started with our services.

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: